Part 1 – Who Are We?

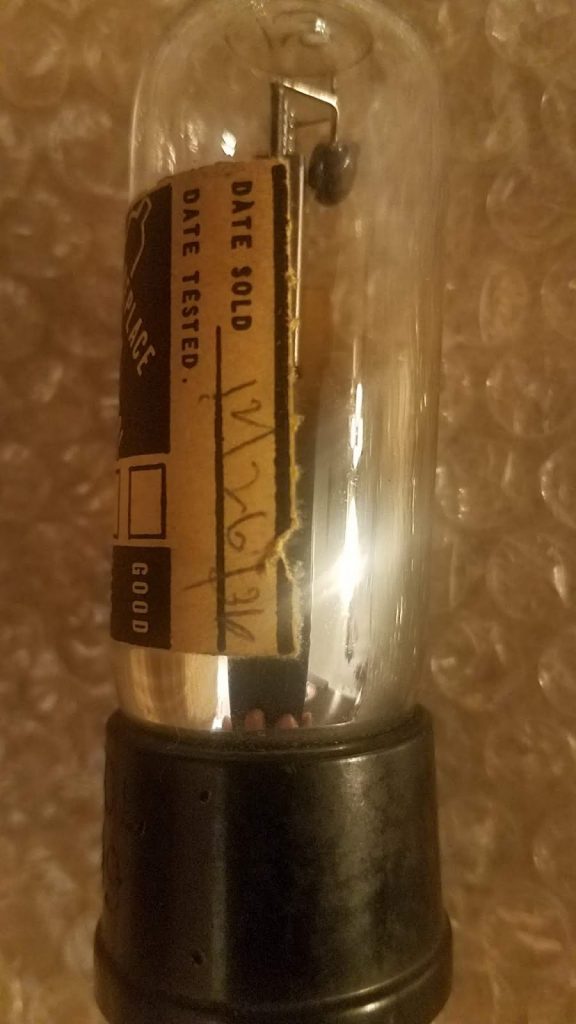

As one might guess, I love radio. I grew up surrounded by vacuum tube equipment and I love old vacuum tube radios. When my friend, Todd, mentioned that a 1925 vintage RCA Radiola 20 was coming into his possession, and he wanted to restore it, I was more than a little interested. Todd had known this radio since childhood, but had never seen it in operation.

Todd is a broadcast engineer with decades of experience operating, repairing, installing, and upgrading AM and FM broadcast radio transmitters. Radio is in his blood.

From 1973 to 1978, I ran a Hammond Organ repair business in Los Angeles, which found me constantly working on vacuum tube equipment, sometimes dating back to the mid-1930s. The Radiola 20 is ten years older than that. Technology improved very quickly in those days. The tubes used in the Radiola in 1925 were already obsolete by 1931. Since the Radiola operated on primary batteries (dry cells), it was designed for minimum power consumption. This radio will not help warm your sitting room, it runs cold. There was much to be learned here and we were both very excited.

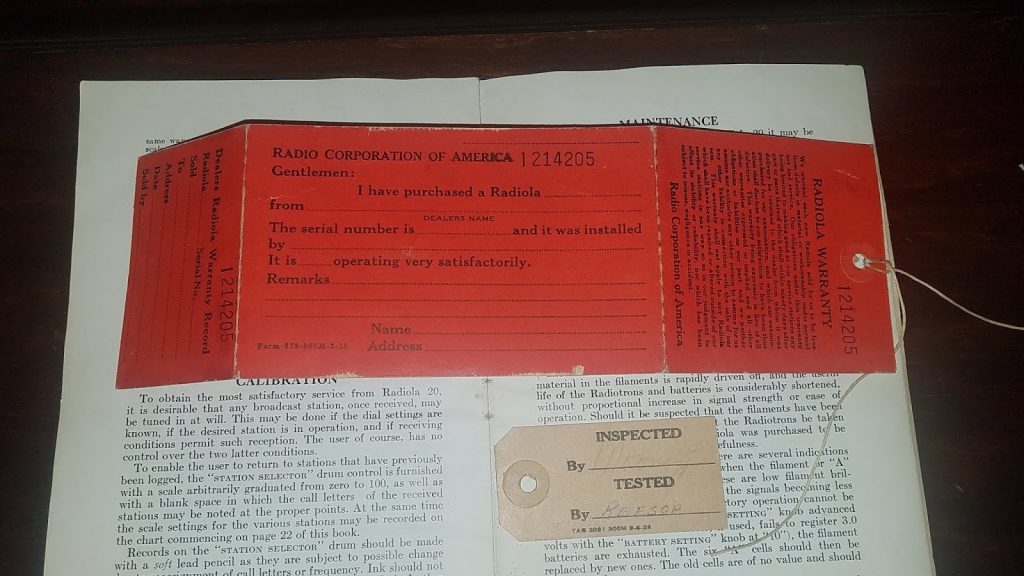

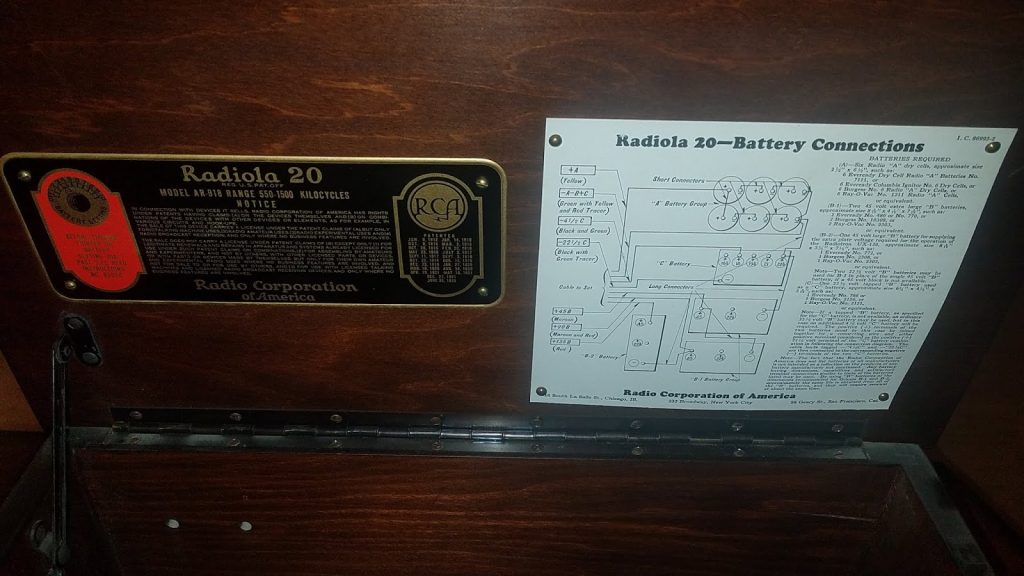

While we were waiting for the radio to ship and arrive, we did research on every aspect of the radio we could find. It took a lot of digging on the Internet and we assembled pretty much everything there is to know and every bit of documentation and literature ever published about the Radiola 20. We found the owners manual and setup guide, RCA’s schematics, technical notes, service notes, and troubleshooting guide for radio repairmen, plus more service notes published by Gernsback. We also drew a modern style schematic using KiCAD. When the radio arrived, Todd found it to be in near pristine condition, like new, and all the original paperwork that came with it was there, including the warranty card. This was a museum quality radio perfect for taking modern color photos of the internals.

With all this information we collected on our hands, we decided to share it here in one place for others to use. A blog is not the ideal medium for this but it has the advantage of stability and permanance. While researching this information, we often ran into items that had been published on personal web sites many years before that no longer existed, dead links, and photos that were no longer hosted. It’s sad when that happens. Publishing on Blogger and a private blog should avoid this problem for as long as possible. With luck, one of them will be captured in the Internet Archive.

Part 2 – The Radiola 20 is Special

Lots of different kinds of radios were being made in 1924, 1925. The RCA Radiola 20 is special because it was the first radio that was both reasonably priced and easy to use. Early radios were difficult to tune and wouldn’t stay on frequency. They required constant fiddling with the controls. At this time, the first superheterodyne radios were appearing. They were easy to use but were large, required a lot of parts, a lot of power, and were priced from $500 to $700 — the price of a new automobile. That’s $7,300 to $10,220 in today’s dollars. Only the wealthy could afford that kind of money for a radio. The Radiola 20 sold for about $100 or $1,460 in today’s dollars. Still, a sizeable purchase, but a lot less than ten grand.

The Radiola 20 is a major engineering achievement and results from the melding of several aspects of radio technology. To appreciate this radio requires a basic grasp of those technologies. This understanding does not require technical knowledge, nor math. Since I don’t know the reader’s knowledge of these things, I will delve briefly into all the background and history leading up to radio, without getting too technical. I’ll also discuss some of the fascinating personalities involved in the development of radio — the birthing ground and foundation of modern electronics.

If you already know the history and different radio design types, you can skip the rest of this section and go to Part 3. If you don’t know, I will cover more detail here than is absolutely necessary, but it will give you a more complete picture.

What I find interesting is how quickly technology develops when consumer demand appears. This is easily seen in the development of radio. Since practical radio and the birth of modern electronics are really the same thing, and both depend on the vacuum tube, I’ll begin with that.

Vacuum tubes are based on a phenomenon called thermionic emission. When an object is heated to incandescence (glowing hot), electrons become free to move and easily leave the surface of the material. This effect becomes noticeable above 1,300 degrees Fahrenheit and was first noted by Bequerel in 1853. If you put an electric charge on an object in dry air, it will hold the charge for a long time. If you then heat the object to 1,300F, it loses the charge. Bequerel observed this but didn’t know why it happened.

Over the next 30 years, the thermionic effect was repeatedly forgotten and rediscovered by different researchers. It was rediscovered again by Edison in 1880 when he was trying to discover why his incandescent lamps seemed sensitive to polarity when run on direct current. When they failed, the positive end of the filament was darkened more than the negative end. The answer was that not all of the current was traveling through the entire filament. Some of the current was somehow traveling through the vacuum in the light bulb and striking the most positive end of the filament. He made special bulbs with an extra electrode inside to measure the effect and it’s named after him: the Edison Effect. He filed a patent for a voltage regulator that used the effect. Edison didn’t see any practical use for it, nor did he understand why it happened. By the way, this was the very first US patent for an electronic (not electrical) device.

Some experimentation with thermionic emission took place over the next 20 years, but not much. The next step was taken by Ambrose Fleming. Since the Edison Effect resulted in conduction in just one direction, a diode, he surmised this might be useful for the detection of radio waves. He was right. It worked better than a crystal, and vastly better than the mechanical cohering detectors used to detect spark transmitter signals in the early 1900s. He patented the diode in 1904. It consisted of a small heated filament, as in a light bulb, and a plate electrode. The device looked liked a small light bulb.

It’s interesting that thermionic emission was not understood until the advent of quantum physics. It was the subject of the 1928 Nobel Prize in physics. Even today, in 2018, physicists still argue over certain fine points that underlie thermionic emission.

At this time, around 1904, the only way to transmit radio waves was with high-voltage spark transmitters or large high-frequency mechanical alternators. These could only be used with Morse Code. There was no speech or music, no audio. Radio was used by the military, by ships at sea, and by radio amateurs (hams). Transmissions were noisy and broad so often only one transmitter in a region could operate at a time because of interference, and there was deliberate jamming. It was chaos.

The next step was a giant one. Lee De Forest was a great promoter of radio with a long and tumultuous career that began in the 1890s. In 1905 and 1906, he was desperately trying to come up with a radio detector that worked well and that didn’t run afoul of the multitude of patents that already existed. He was working with Fleming type diode tubes and wondered what would happen if he inserted a grid of wires between the cathode and anode, and connected the antenna signal to the grid. It worked and he was granted a patent for his invention in 1908. De Forest wasn’t much of a scientist and didn’t understand how it worked, but he had invented the first electronic amplifying device. A small voltage on the control grid could control a much larger current flowing from the filament to the plate electrode.

It is impossible to overstate the importance of this invention — a device capable of power gain. He called his invention the Audion. De Forest himself and many others greatly underestimated the importance of this invention. De Forest thought it might be useful for a few military applications. In fact, it became the fundamental device at the heart of radio, telephone, television, radar, sonar, computers, and countless devices of the electronic age until the transistor was invented in 1947. It took 25 more years, into the late 1960s, for the transistor to largely supplant the vacuum tube. Even today, some applications are best handled by vacuum tubes.

An important detail is that De Forest’s tubes were not made using a “hard” vacuum, but included a small amount of gas. Little attention was paid to impurities inside the glass envelope. Irving Langmuir surmised that many of the problems with triode tubes of the time, such as non-linearity, instability, and limited frequency response resulted from impurities in the envelope. His development of tubes with a hard vacuum inside and scrubbed of all impurities solved the problems. Fleming diodes could only handle low voltages. Langmuir’s could handle hundreds of thousands of volts. Langmuir’s triodes were linear, with higher gain, much higher frequency response, and could handle high voltage. The true vacuum tube was born. This work occurred around 1913 and triggered the rapid adoption of vacuum tubes in long-distance telephone amplifiers. The first transcontinental phone call happened in 1915.

Early radio (the electrical era of radio) had many fathers, including Maxwell, Hertz, Tesla, Marconi, De Forest, and others. Modern radio (the electronic era) had just one father, Edwin Armstrong. Every type of radio receiver in use today was invented by Armstrong. In 2018, one can say that every radio device you’ve ever used, from AM, FM, shortwave radios, to cellphones, garage door openers, or wireless thermometers, was either a superheterodyne or superregenerative design. Armstrong was a brilliant scientist and inventor.

While growing up, Armstrong had experimented with the flawed and gassy De Forest audion tubes and desired to gain a full scientific understanding of how they worked, which was unknown. By 1912 there was a basic scientific understanding of vacuum tubes, and it was around this time that Armstrong made his breakthrough invention of “regeneration”.

Audion tubes and early vacuum tubes were primitive and had low performance compared to later vacuum tubes. They had low gain (they amplified, but not by much) and had high interelectrode capacitance, which greatly limited performance. Armstrong discovered that using positive feedback resulted in stunning increases in gain. Instead of an amplifier stage producing a gain of 8 or 10, Armstrong obtained gains of 10,000 and more in a single stage, while using the mediocre tubes of the time. In 1913, Armstrong prepared demonstrations of his invention, scientific papers, and he applied for a patent. The patent issued in October of 1914.

In 1914, Armstrong was an undergraduate at Columbia University, studying electrical engineering. There, he presented the first scientific paper that fully characterized De Forest’s audion tube, complete with oscillographs showing the “characteristic curves”. It amazing that it took six years for someone to do that work. It’s also amazing that the manner in which Armstrong presented the data is the same way we illustrate device data for transistors today.

De Forest discounted Armstrong’s invention and filed a series of competing patents that essentially copied Armstrong’s claims, stating that he discovered regeneration first. Obviously, De Forest realized the importance of the invention. Competing claims were also filed by Alexander Meissner of Germany and Langmuir at General Electric. This was the beginning of many court battles that continued into the 1930s, with lawsuits, and countersuits, and two cases before the US Supreme Court. It seems that whenever there’s an important invention, this happens. In one of the early court cases, Armstrong and De Forest argued face to face. Armstrong easily demonstrated to the court that De Forest hadn’t the faintest idea how his audion tubes worked or how regeneration worked. Yet, the courts finally found in favor of De Forest, which today, is just stunning. The entire engineering community was shocked and appalled, but that’s how it ended up.

Another example of this kind of injustice was Marconi winning the patent battles and the title “Inventor of Radio”. He even won the 1909 Nobel Prize. Fortunately, this miscarriage of justice had a just but too-late outcome. It took 40 years for the courts to finally overturn the previous decisions in favor of Marconi and award inventorship to Nikola Tesla. After all, Tesla was using radio for remote control purposes when Marconi was but a child. However, it was too late and Tesla died penniless.

There are many more examples of such injustices. The takeaway is that the showman always wins. The person who wins is not the smarter person, but the person who is the better promoter, the better politician, the better financier, and the better people-person.

Armstrong’s invention of the regenerative radio was the right invention at the right time. One vacuum tube and a few parts, some of which could be made by hand, resulted in a high-performance radio. Anyone who was interested could afford to make one. What do I mean by high-performance? High-performance means a radio that can capture signals all the way down to the noise floor, the limit of what is possible. (There are modern digital techniques that can get quite a way below the noise floor using computers, but none of that was even dreamt of in 1914.)

What is the noise floor? As you make a radio receiver more and more sensitive, you run into an electrical noise limit that cannot be avoided. Natural and man-made electrical noise sets this limit. In the AM radio band, which is what we’re discussing, this noise floor is quite high. There are 15,000 lightning strokes on Earth every second, and each contributes to the noise. Cars, power lines, and electrical equipment radiate noise. Thermal noise in the antenna adds more. You can’t get around physics. The regenerative radio readily reaches this noise limit. You can’t do any better in terms of sensitivity no matter what kind of radio you design.

But, there are no regenerative radios made today, except by hobbyists for fun. This is because the regen has some major drawbacks. It takes skill to tune a regen. To tune in a signal, you have to operate two controls at once. Once it’s tuned, it’s unstable. Changes in temperature, drafts, wind moving the antenna wire, even your hands near the radio cause the tuning to drift. A regen needs constant readjustment. It was great for pioneer enthusiasts, but it’s not a good consumer product that can be set once and left to play for hours.

In addition to sensitivity, a radio must be selective. It must have a narrow enough bandwidth that you only receive the desired signal and not several others at the same time. If you’ve used a crystal radio in an urban environment with lots of radio stations, you know the problem. No matter what you do, you hear more than one station at the same time. If there is only one strong signal it’s okay. The regenerative radio achieves both high gain and high selectivity using almost no parts. This is great, but it has the instability problems mentioned above and other problems of a technical nature that I won’t get into here.

In 1916, Alexanderson patented the TRF radio (Tuned Radio Frequency). Without regeneration, tubes didn’t provide enough gain for a tuned circuit to be sufficiently selective to receive just one station. His idea was to cascade several stages of tuning and amplification — each feeding the next. This actually works well enough if you cascade five to seven such stages. The problem with the TRF is each stage must be independently tuned to the same frequency or you get almost no signal out the end of the chain. Tuning is extremely challenging and requires great patience. Tuning for a certain signal is a process of successive approximation. TRF radios were equipped with precision dials, so that the settings could be written down and found again later. The TRF works. It’s stable. Once tuned, it stays put. But it’s very user-unfriendly.

Many attempts were made to gang-tune the stages of a TRF. In other words, to drive all the tuning capacitors from a common shaft and a single knob. But it couldn’t be done. The mechanics and precise matching of the capacitors was impossible.

Part 3 – The Radiola 20

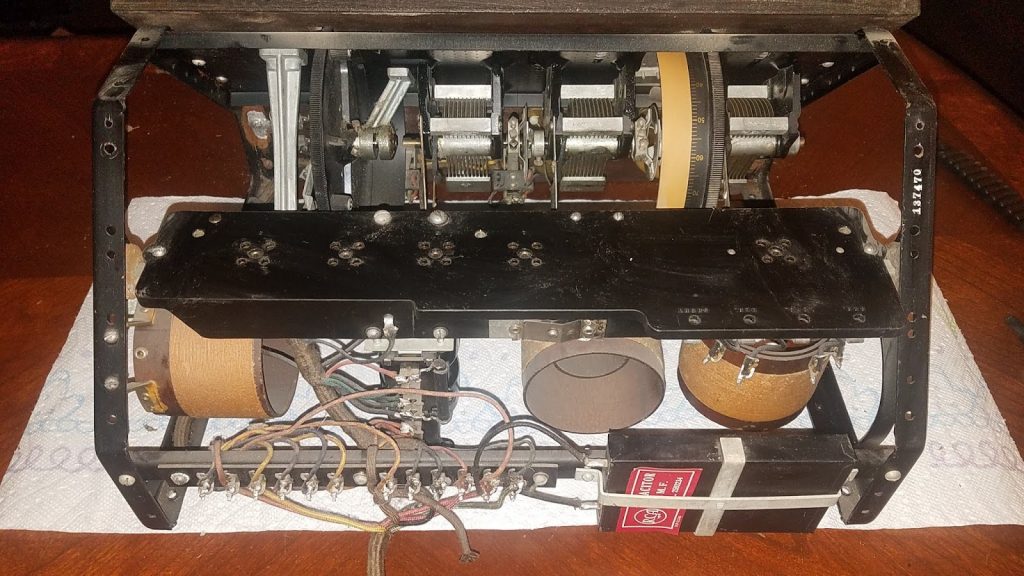

Which brings us to the Radiola 20. I haven’t explained the superheterodyne radio, also invented by Armstrong, because it’s not necessary for this story. All consumer AM and FM radios made since 1935 are superhets. The superhet solved all of the above problems, but required a lot of parts, a lot of power, and cost a fortune. In 1924, RCA wanted to come up with a radio that was consumer friendly and didn’t cost a fortune. Armstrong was on the RCA staff when the Radiola 20 was designed, so he surely had a hand in it. RCA came up with an efficient hybrid design that used only three stages of TRF plus a small amount of regeneration. Precision manufacturing of the tuning capacitors and mechanics enabled RCA to achieve usable gang-tuning of three stages of TRF using a single dial. This provided enough selectivity, but not enough gain, so the third TRF stage includes some regeneration. This trick was possible because they had the inventor of regeneration, Armstrong, along with his patents, on staff. Melding these two technologies was clever and effective.

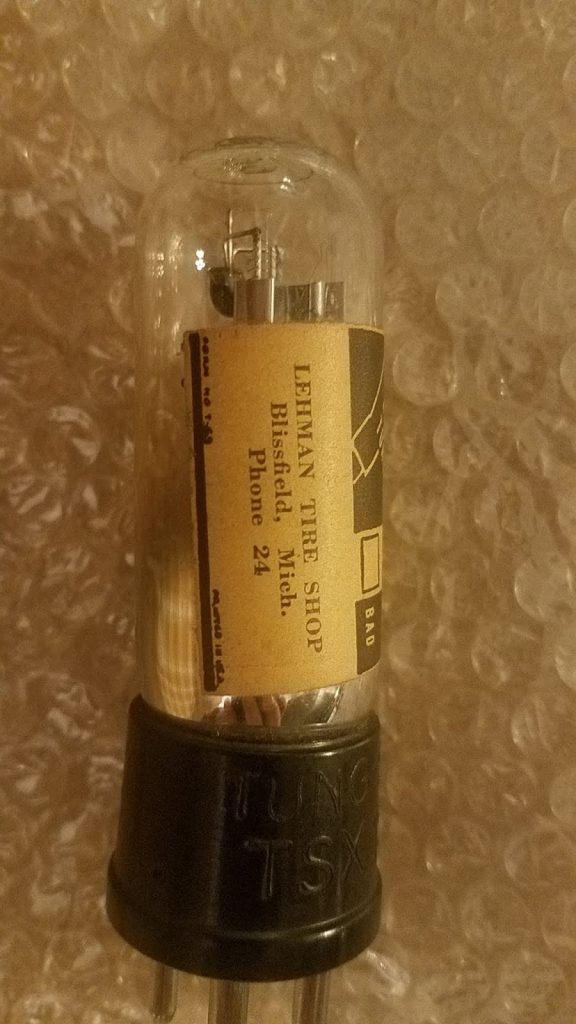

The result is a radio using only four low-power X-99 tubes, that just sips battery power, that tunes frequency with a single dial. The second dial, called “Amplification” is the regeneration control. Since the tuning is TRF-style, the radio is stable. Tune it once and it plays all day. A fifth vacuum tube is an audio power amplifier that delivers nearly one watt of room-filling audio to the optional speaker. If you’re listening in headphones, you can unplug the fifth tube and save power. The Radiola 20 sold for $115 at introduction in 1925, dropping to $102.50. RCA sold 135,121 of these radios. That’s about $225 million in sales in 2018 dollars.

The Radiola 20 was a radio for the masses. It was affordable and anyone could learn to use it.

If you own one of these pieces of electronic history and are interested in the information we gathered, there’s a link in the comments below. The link enables you to download an 80 MB zip file containing everything we could find on the Radiola 20 and many other radios from that time period.

Recent Comments